Focusing on the efficiency improvement data of continuous injection molding process compared to traditional shoe-making technology

The footwear industry has witnessed significant advancements in manufacturing processes, particularly in the production of labor protection shoes. One of the most notable innovations is the continuous injection molding process, which offers substantial efficiency improvements over traditional shoe-making techniques. This blog explores the data-driven benefits of this modern approach and its impact on productivity, cost-effectiveness, and quality.

Traditional Shoe-Making Technology: Challenges and Limitations

Traditional shoe manufacturing relies on labor-intensive processes such as cutting, stitching, and assembling multiple components. For labor protection shoes, this often involves:

- High manual labor requirements

- Longer production cycles

- Inconsistent product quality

- Higher material waste

These factors contribute to increased costs and reduced scalability, making it difficult to meet growing demand efficiently.

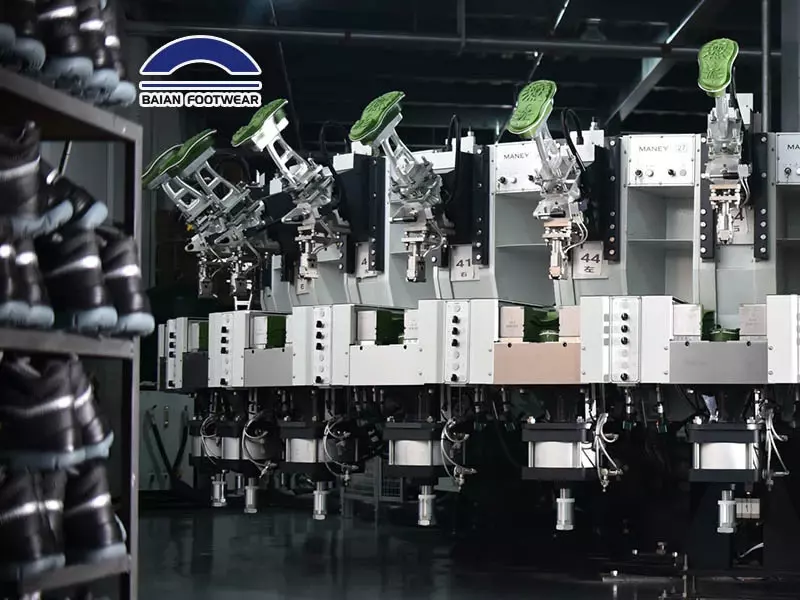

The Continuous Injection Molding Process: A Game-Changer

The continuous injection molding process revolutionizes shoe production by integrating automation and precision engineering. Key advantages include:

- Faster Production: Injection molding reduces cycle times by up to 50% compared to traditional methods.

- Material Efficiency: Minimizes waste through precise material usage, lowering costs by20-30%.

- Enhanced Durability: Seamless construction improves the longevity of labor protection shoes.

- Consistency: Automated processes ensure uniform quality across all units.

Efficiency Improvement Data

Comparative studies highlight the measurable benefits of continuous injection molding:

| Metric | Traditional Method | Injection Molding |

|---|---|---|

| Production Time (per pair) | 30-40 minutes | 10-15 minutes |

| Material Waste | 15-20% | 5-8% |

| Labor Cost | High (multiple workers) | Low (automated) |

Why This Matters for Labor Protection Shoes

Labor protection shoes demand high durability and safety standards. The continuous injection molding process not only meets these requirements but also enhances:

- Worker Safety: Fewer manual processes reduce workplace injuries.

- Cost Savings: Lower production costs make protective footwear more accessible.

- Sustainability: Reduced waste aligns with eco-friendly manufacturing goals.

Conclusion

The shift from traditional shoe-making to continuous injection molding delivers undeniable efficiency gains, particularly for labor protection shoes. By embracing this technology, manufacturers can achieve higher productivity, lower costs, and superior product quality—key factors in a competitive market.

Stay ahead of industry trends by adopting innovative manufacturing solutions that prioritize efficiency and performance.